-

You're Here for Your Dream Kitchen. So Are We.

Whether you’re tackling a small remodel or a major renovation, chances are you are looking for a kitchen that revolves around you. Your style. Your needs. Your life. You’ve come to the right place.

Get Inspired

You're Here for Your Dream Kitchen. So Are We.

Whether you’re tackling a small remodel or a major renovation, chances are you are looking for a kitchen that revolves around you. Your style. Your needs. Your life. You’ve come to the right place.

Get Inspired -

Can’t Go Wrong Combinations.

Countless kitchens have been designed with these exact combinations throughout the years and for good reason. When it comes to these tried and true match-ups, you really can’t go wrong.

Checkout Our Best-Sellers

Can’t Go Wrong Combinations.

Countless kitchens have been designed with these exact combinations throughout the years and for good reason. When it comes to these tried and true match-ups, you really can’t go wrong.

Checkout Our Best-Sellers -

A Place For Everything. Everything In Its Place.

Your kitchen is a workspace where both family meals and the family plans are made. Browse our storage solutions, see them in action and take note of which options may help simplify your day-to-day routine.

Must Have Storage Solutions

A Place For Everything. Everything In Its Place.

Your kitchen is a workspace where both family meals and the family plans are made. Browse our storage solutions, see them in action and take note of which options may help simplify your day-to-day routine.

Must Have Storage Solutions -

Make Your Kitchen Happen

With so many decisions to be made, your kitchen renovation can quickly turn from exciting to overwhelming. That’s where we come in. Stay organized with our Kitchen Planner!

Cardell’s Kitchen Project Planner

Make Your Kitchen Happen

With so many decisions to be made, your kitchen renovation can quickly turn from exciting to overwhelming. That’s where we come in. Stay organized with our Kitchen Planner!

Cardell’s Kitchen Project Planner -

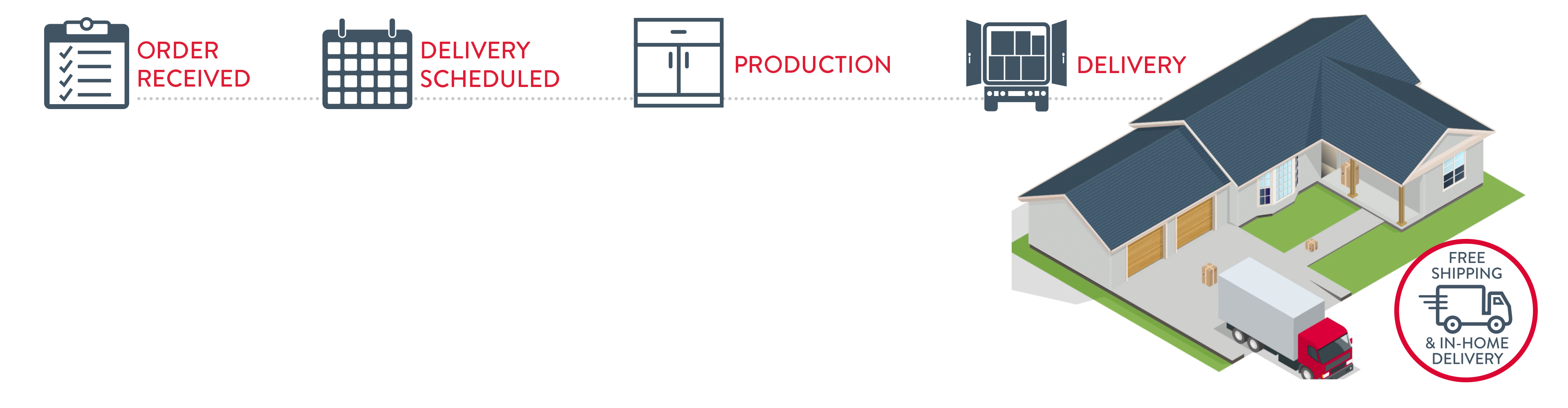

Free Shipping In-Home Delivery - What to Expect

When ordering a Cardell® kitchen, we make sure you are informed throughout the entire process – from order to project completion.

Free Delivery

Free Shipping In-Home Delivery - What to Expect

When ordering a Cardell® kitchen, we make sure you are informed throughout the entire process – from order to project completion.

Free Delivery

A better process is here.

Cardell gives you the freedom to find cabinetry that meets your needs. With our FREE Home Delivery Service and our two collections, you’ll find the right cabinetry at the right price.

Loading... Please wait...

Loading... Please wait...